5 Tips Universal Joint

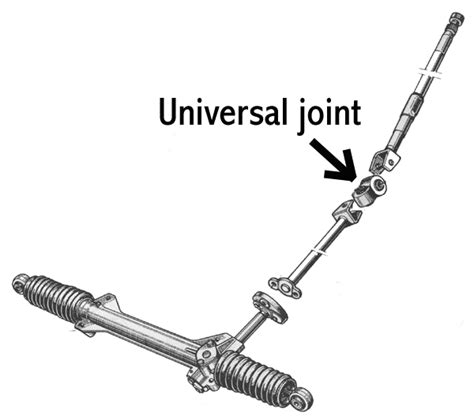

Introduction to Universal Joints

A universal joint, also known as a U-joint, is a crucial component in many mechanical systems, including vehicles, industrial equipment, and more. Its primary function is to transmit rotational power from one shaft to another, even when the shafts are not in a straight line. This flexibility makes universal joints indispensable in a wide range of applications. Understanding how to work with, maintain, and troubleshoot universal joints is essential for anyone involved in mechanics, engineering, or operations that rely on these components.

Understanding Universal Joints

Before diving into the tips, it’s essential to have a basic understanding of how universal joints work. A universal joint consists of two yokes connected by a cross-shaped member. Each yoke is attached to a shaft, and the cross allows the joint to bend while still transmitting power. This design enables the universal joint to operate effectively even when the shafts are at an angle to each other.

Tips for Working with Universal Joints

Here are five valuable tips for working with universal joints, covering selection, installation, maintenance, and troubleshooting:

Proper Selection: Choosing the right universal joint for your application is critical. Consider factors such as the operating angle, speed, and torque requirements. Using a universal joint that is not suited for your application can lead to premature wear, failure, and potentially dangerous situations. Always refer to the manufacturer’s specifications and guidelines for selection.

Correct Installation: The installation of a universal joint is as important as its selection. Ensure that the yokes are properly aligned and secured to the shafts. Misalignment can lead to uneven wear and reduce the lifespan of the joint. It’s also crucial to follow the manufacturer’s instructions for installation, as different types of universal joints may have specific requirements.

Regular Maintenance: Regular maintenance is key to extending the life of a universal joint. This includes lubricating the joint as recommended by the manufacturer, inspecting for signs of wear, and replacing worn-out parts. Lubrication is particularly important, as it helps reduce friction and prevents corrosion.

Troubleshooting: When issues arise, being able to troubleshoot effectively can save time and money. Common problems include vibration, noise, and a decrease in performance. These issues can often be traced back to misalignment, lack of lubrication, or worn-out components. Always start with the simplest potential causes and work your way up to more complex issues.

Safety Precautions: Finally, safety should always be a top priority when working with universal joints. Ensure that the system is properly shut down before starting any maintenance or repair work. Wear appropriate protective gear, and be aware of any potential hazards such as rotating parts or hot surfaces.

🛠️ Note: Always refer to the specific guidelines and recommendations provided by the manufacturer of your universal joint, as different models and types may have unique requirements and considerations.

Applications and Variations

Universal joints are used in a wide range of applications, from automotive and aerospace to industrial machinery and robotics. Each application may require specific types of universal joints, such as single or double cardan joints, depending on the operational requirements. Understanding the different types and their applications can help in selecting the most appropriate universal joint for your needs.

Conclusion Summary

In summary, working effectively with universal joints requires a combination of understanding their basic operation, selecting the right type for the application, installing them correctly, maintaining them regularly, being able to troubleshoot issues, and always prioritizing safety. By following these tips and staying informed about the specifics of the universal joints you work with, you can ensure optimal performance, reliability, and longevity of the mechanical systems they are a part of.

What is the primary function of a universal joint?

+

The primary function of a universal joint is to transmit rotational power from one shaft to another, even when the shafts are not in a straight line.

Why is proper lubrication important for universal joints?

+

Proper lubrication is important for universal joints as it helps reduce friction, prevents corrosion, and extends the lifespan of the joint.

What are common issues with universal joints?

+

Common issues with universal joints include vibration, noise, and a decrease in performance, often due to misalignment, lack of lubrication, or worn-out components.